Project

Idea

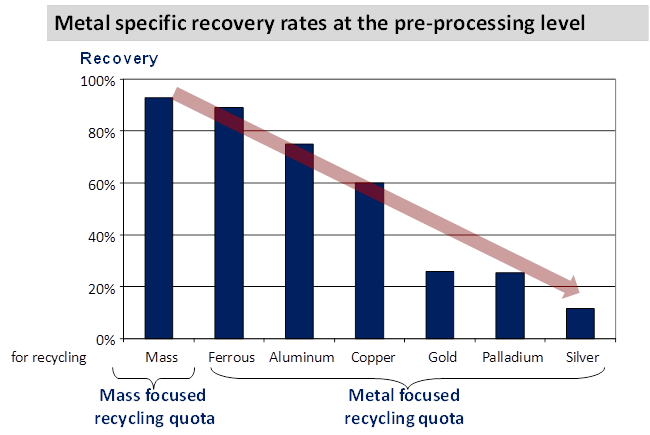

Electrical and electronic equipment (WEEE) are due to their increasing levels of highly functional, strategically relevant metals an important source of raw materials. Due to legal and economic framework previously existing recycling processes are not technically optimized for these tasks. At the same time apply "recycling restrictions" as a core indicator for the classification of metals as critical.

Chancerel, P.; Meskers, C.; Hagelueken, C.; Rotter, V. S.

Assessment of metal flows during pre-processing of waste electrical and electronic equipment focusing on precious metals. Journal of Industrial Ecology Volume 13, Issue 5, October 2009, Pages: 791-810

Goals

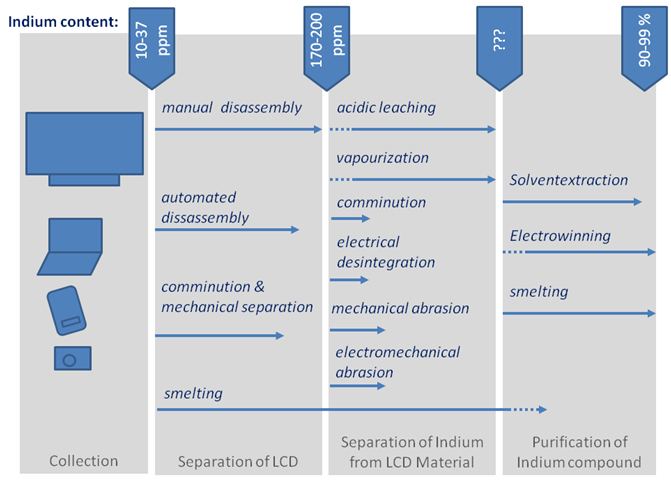

The project aims to achieve in the treatment of WEEE and its components at all stages of the recycling chain, the accumulation of selected metals by new and improved processes and process chains to improve their recovery within existing recycling systems to minimize losses and to close circuits. Thus strategic dependency on imported raw materials can be reduced through enhanced recycling and pollution in primary production can be avoided.

Approach

The research approach is based on creating a value substances register for WEEE and experimental studies of technical and organizational processes to dissipate losses of trace metals in the current recycling system. With partners experimental flow analysis of selected treatment and treatment processes are carried out along the recycling chain, serving the direct process optimization. Based on new enrichment methods are developed that target hitherto inadequately reclaimed metals. In addition, "Design for Recycling" recommendations are specific for trace metals.

Target metals of the project are:

Antimony, gallium, germanium, indium, cobalt, tantalum, tin, rare earth elements